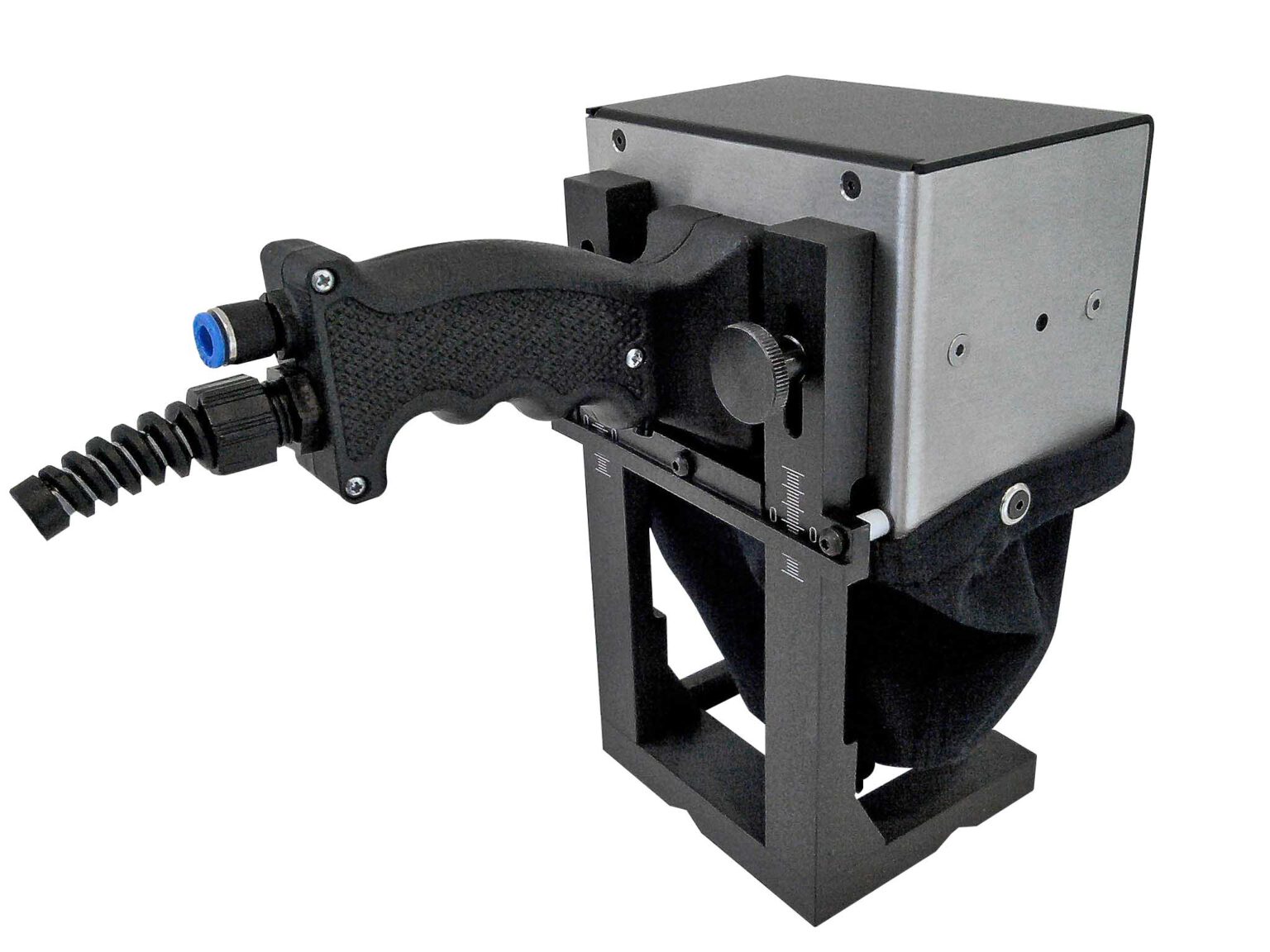

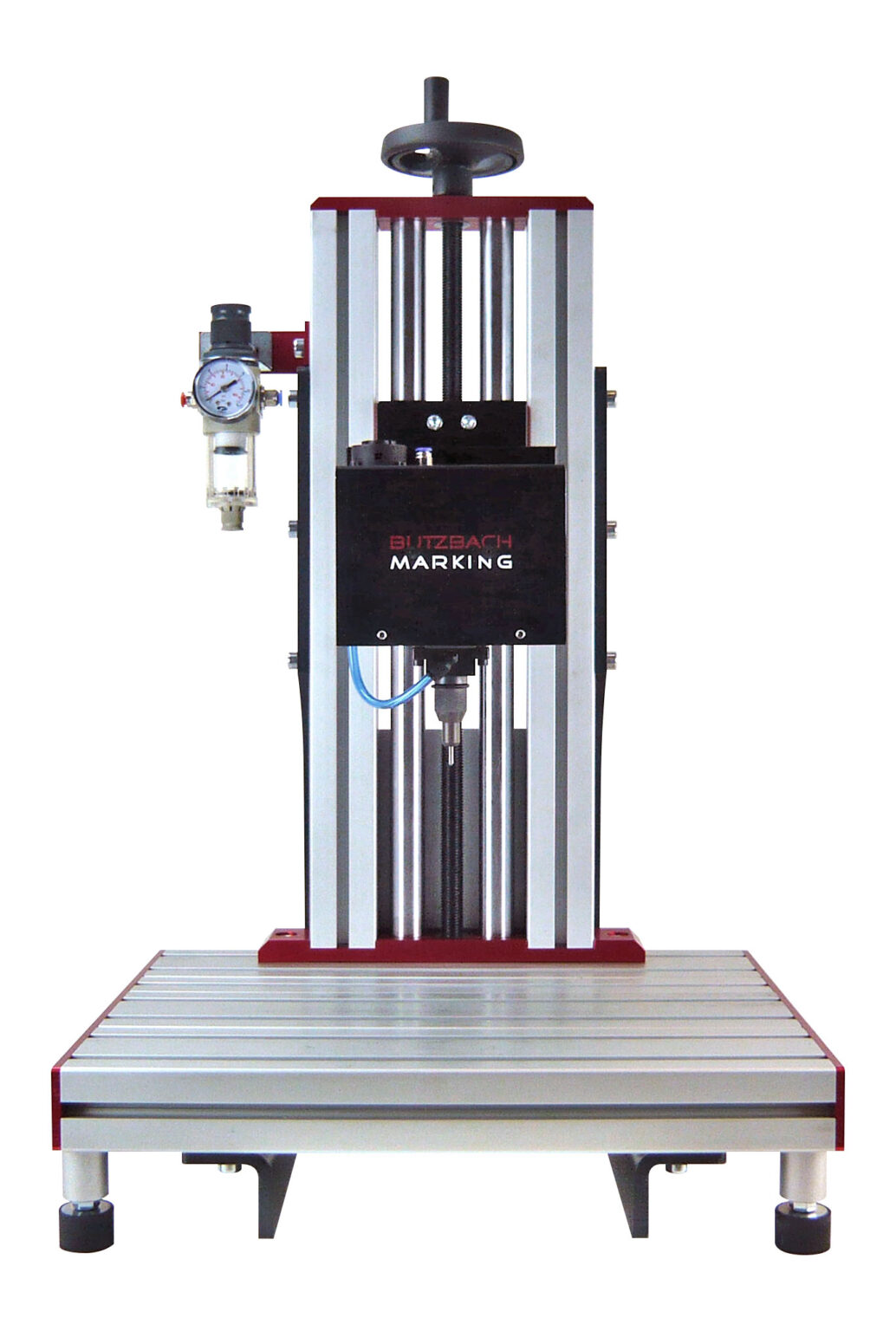

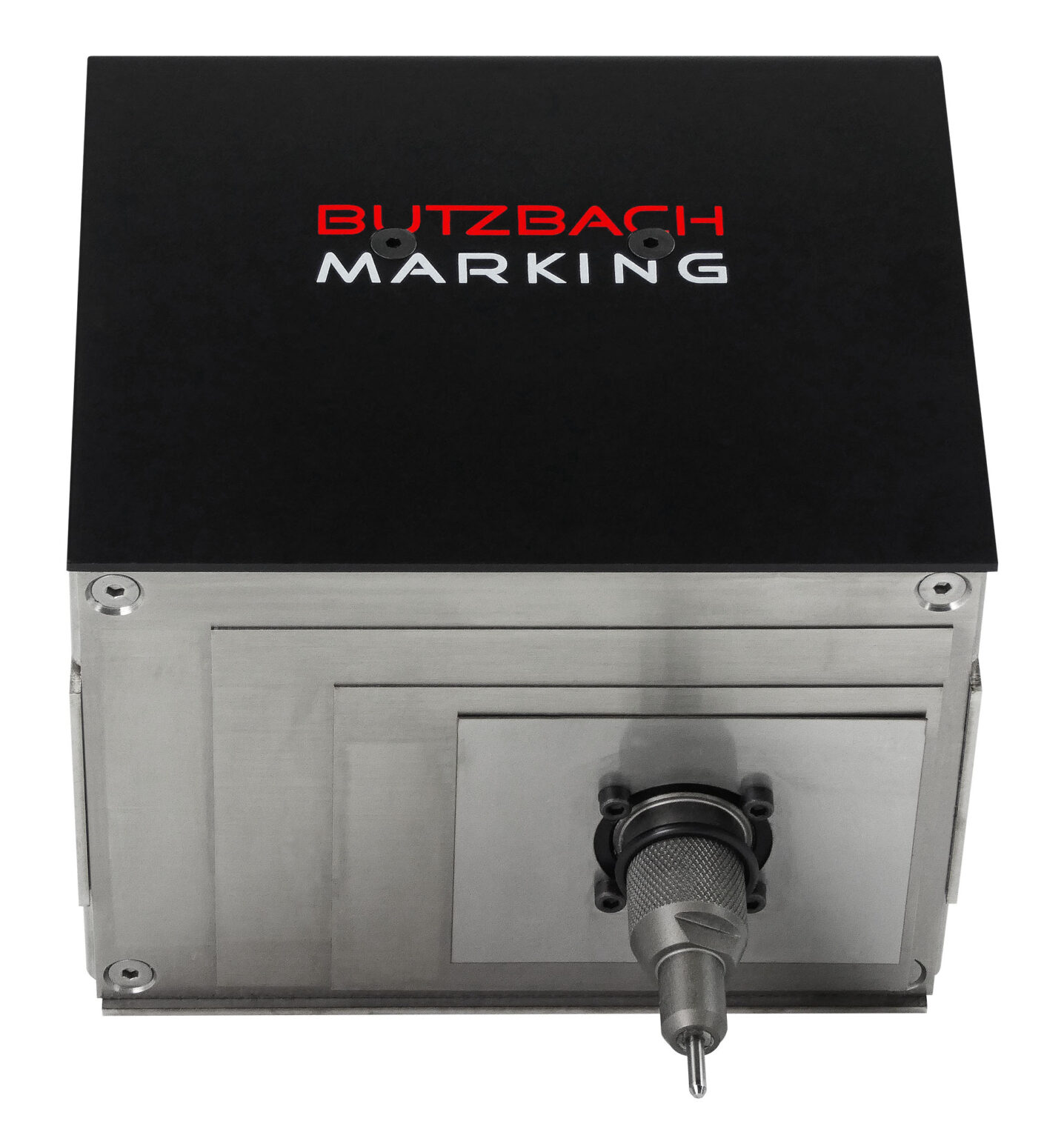

Battery operated portable dot marking unit BM53 Mobile

- Marking area 60 x 40 mm

- Patented differential system with fixed drive®

- Suitable for 3-shift operation

- Fitted with THK guides

- Marking depth to 0.4 mm in steel

- Up to 12 symbols/second

- New non-slip stand frame e.g. for:- Frontal marking of pipes and shafts from 35 mm diameter- Axial and radial marking of pipes and shafts- Marking of straight, vertical and horizontal surfaces